We are pleased to announce that a new member has been added to our extensive family of partners – Nano Dimension. It provides intelligent machines to fabricate Additively Manufactured Electronics (AME). Innovative manufacturing technology opens up new and unprecedented opportunities for those looking for fast and uninterrupted 3D printing solutions to prototype electronic circuits.

AME Technology

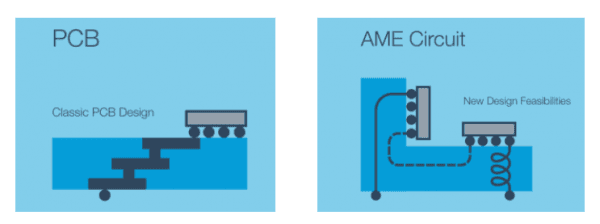

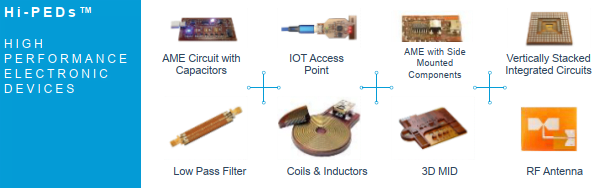

Additive Manufacturing Electronics (AME) technology is a unique technique to print Hi-PEDs – High-Performance Electronic Devices, layer by layer, from scratch. HiPEDs are electronic boards with complex geometries that cannot be produced in traditional PCB manufacturing.

DragonFly LDM™ Printer

The principle of the innovative AME technique is straightforward. Using a special DragonFly LDM ™ printer, the electronic components required for electronic devices are printed by injecting dielectric polymer and conductive silver ink. This technique allows users to 3D-print more functioning electronic circuitry faster, extending DragonFly’s rapid prototyping capabilities beyond prototyping. In addition, the printer also features a Lights-Out Digital Manufacturing (LDM) printing system, the only printing platform in the industry that covers all production processes, ensuring continuous and around-the-clock 3D printing of electronic circuitry.

At the touch of a button, a functional 3D printed smart device is produced in just a few hours from a computer-aided design. AME technology also guarantees a significantly faster production and optimization process, where different electronic components can be printed simultaneously.

The printer can print side contacts, inductors, sensors, transformers (AC2AC, AC2DC, DC2DC), RT: Antennas up to 6Ghz, vertically integrated ICs, and more. The DragonFly LDM ™ printer is suitable for producing disposable prototypes and small-scale printed electronics. In addition, LDM ™ digital production technology ensures uninterrupted round-the-clock printing with minimal specialist supervision.

Possibilities with DragonFly LDM™ printer:

- Enables long, uninterrupted runs around the clock, with minimal supervision

- Minimal print job set up and preventive maintenance

- Enables increased design capabilities & manufacturability of components

- Enables on-site prototyping in a matter of hours

- Retention of sensitive IP in-house during development

- Limits environmental impact and reduces waste

Possibilities with DragonFly LDM™ printer:

There is no doubt that 3D printing in the near future will become one of the key innovative digital manufacturing techniques, creating added value in education, science, telecommunications, medicine or electronics, and other industrial fields. We are glad to be one of the first in Lithuania to offer a unique solution that can shorten the time to market your products, reduce production costs and time, allow you to test unprecedented design, significantly improve product performance, reduce CO2 footprints, and more.

Interested? Contact Us:

Products Specialist